Story and photos provided by Steve Saef AA2BB

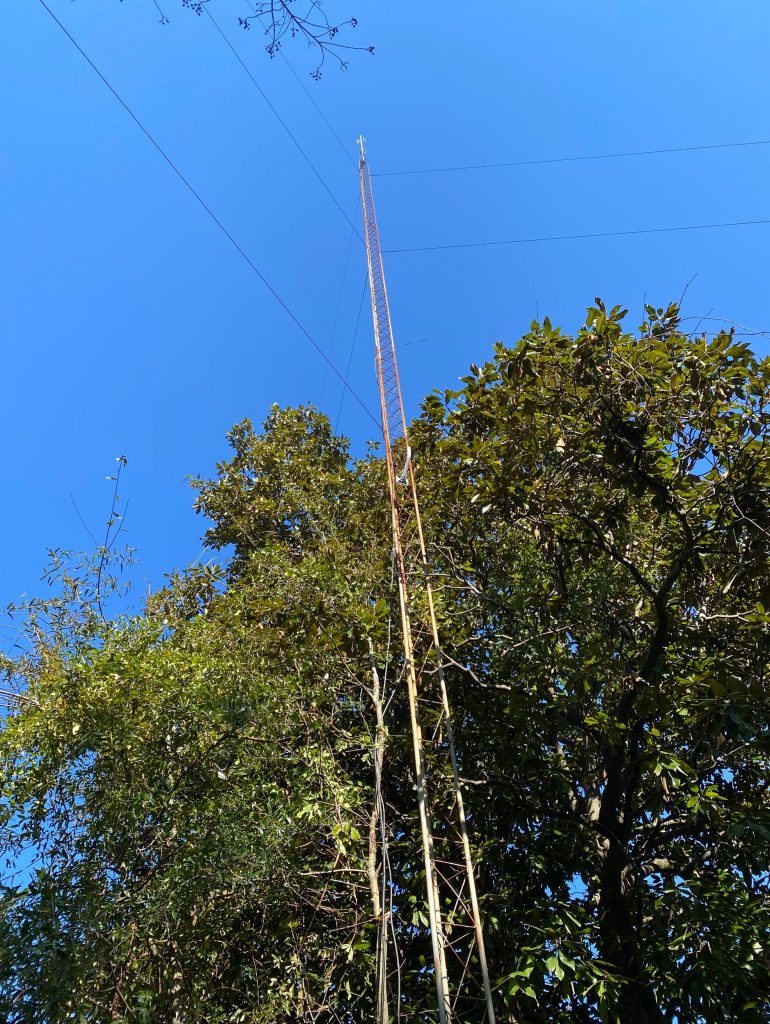

In October of 2021, the new owner of a property in North Charleston contacted the Charleston Amateur Radio Society looking for anyone who could remove a 100 foot antenna tower with a VHF antenna on top. He needed someone with the expertise, experience and equipment to do the job. The message was passed to Bryce Myers, K4LXF, one of a select few in the Charleston area with the necessary qualifications. Bryce contacted the new owner and made arrangements to check out the situation.

Bryce and Rick Valentine, N8BKN, went to the site and inspected the tower. They found it to be in good condition, standing on a concrete pad next to a large magnolia tree near a dilapidated house, inhabited by several wild kittens and cats. On top of the tower was a VHF antenna which, when tested with an antenna analyzer, was found to be resonant on the 2 meter ham band. They decided it was feasible to remove the tower as requested.

Bryce and the new owner of the property made a deal that, in exchange for the work of dismantling and removing the tower, antenna, and guylines, those who did the work of removal could keep the tower, antenna and guy lines.

Bryce assembled the labor team (Rick, Warren Richey, KK4EVI, Lee Miller, KI4LLJ, and myself, AA2BB,) and we began discussions as to how this could be accomplished.

Bryce spent several nights picturing the entire process in his mind before going to sleep. He mapped out all the steps of the procedure in his head well before the actual work began.

Several planning sessions took place during the morning breakfasts at Bojangles on Ladson Road. Weather was a major consideration as Bryce, who would be doing the climbing, does not wear gloves and cold weather causes hand muscles to cramp, something that cannot be tolerated when at altitude on a metal tower. We needed to wait for warmer weather and a dry day. A date was ultimately chosen and the work was begun in early February, 2022.

Our equipment was basic: a ginpole (10′ pole with a pulley at the top,) 200′ of rope, a second pulley to guide the rope from the bottom of the tower, a tagline, a tool bucket, a car jack, Bryce’s climbing belt, and a few wrenches of the proper sizes. Bryce carried a handi-talki to communicate with the ground crew via simplex. A mobile rig was set up at the worksite with a loudspeaker attached so we could all hear Bryce.

10’ GIN POLE AND 200’ ROPE

All members of the team except myself were familiar with the details, having done this many times before. The only unknown was the manner in which the antenna was fastened to the top of the tower. That was something that Bryce could only learn from direct inspection upon reaching the top of the hundred-foot tower.

It is worth digressing here to mention some principles that apply when performing a task of this magnitude:

- The job of the man on the tower is, by nature, a one-man-show. In assuming responsibility for that task, he must have the entire process clearly delineated in his mind’s eye.

- The climber must always be attentive to his attachments to the tower: the rope, his hands or both. The entire process is based on his feel of the tower as he climbs and performs the steps necessary to dismantle it. He is in a virtual cocoon which contains only him and the task at hand.

- NevergetunderBrycewhileheisworking.

- The ground crew must have a thorough understanding of the procedure and be ready to do the things necessary to assist the climber when asked.

- The climber has only 2 hands, but needs 3!

- Bryce has a rule that there must be at least one other person at the site when he is on the tower.

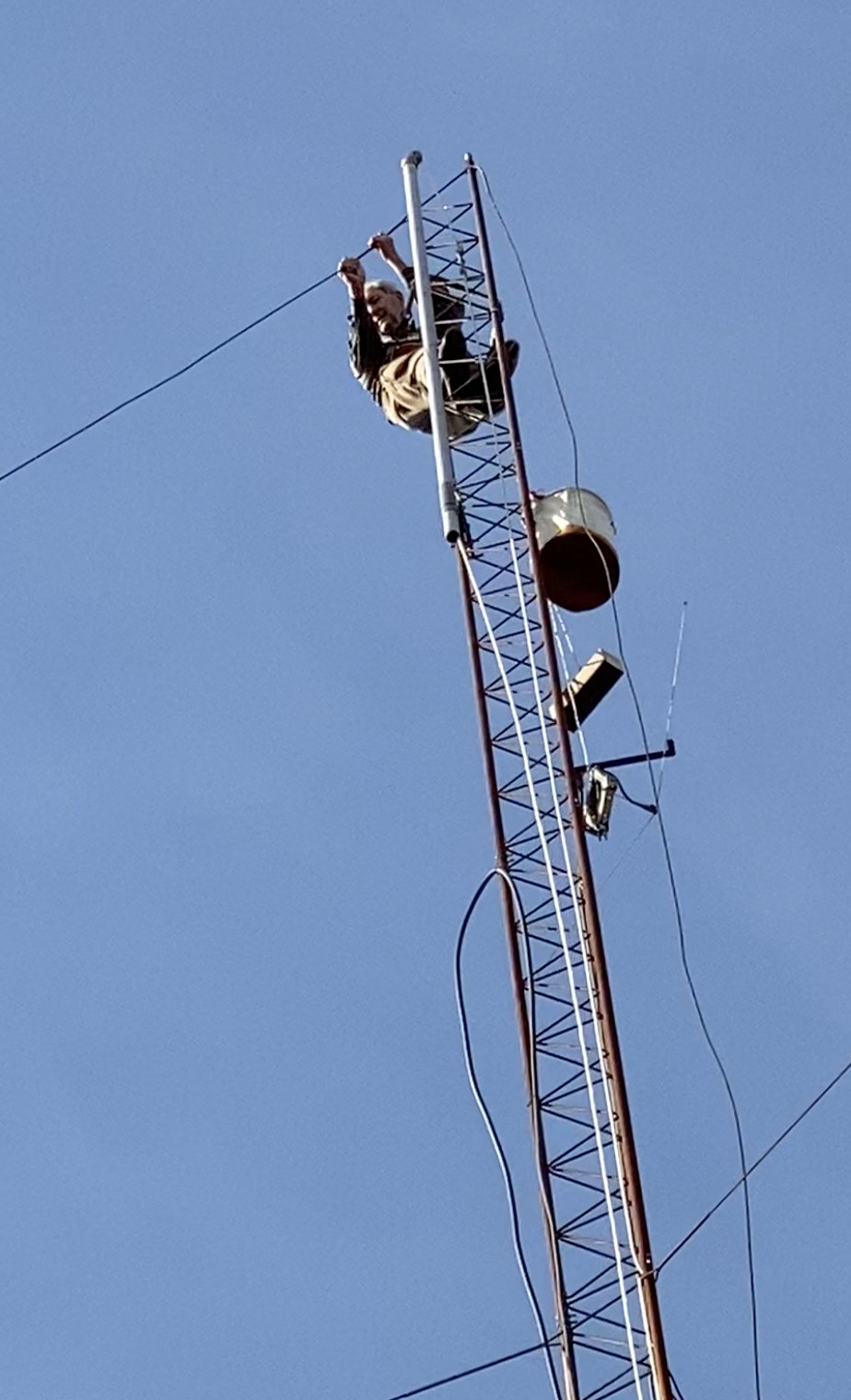

With the plan established, the labor team met at Bryce’s house and traveled together to the antenna site, arriving at approximately 11 AM on the first day. Equipment was laid out, Bryce put on his climbing belt, and stepped onto the tower. Climbing about 25 feet at a time, and stopping to rest for short intervals, he rapidly ascended the entire 100 feet of the tower. Several wild cats who inhabited the property provided an audience.

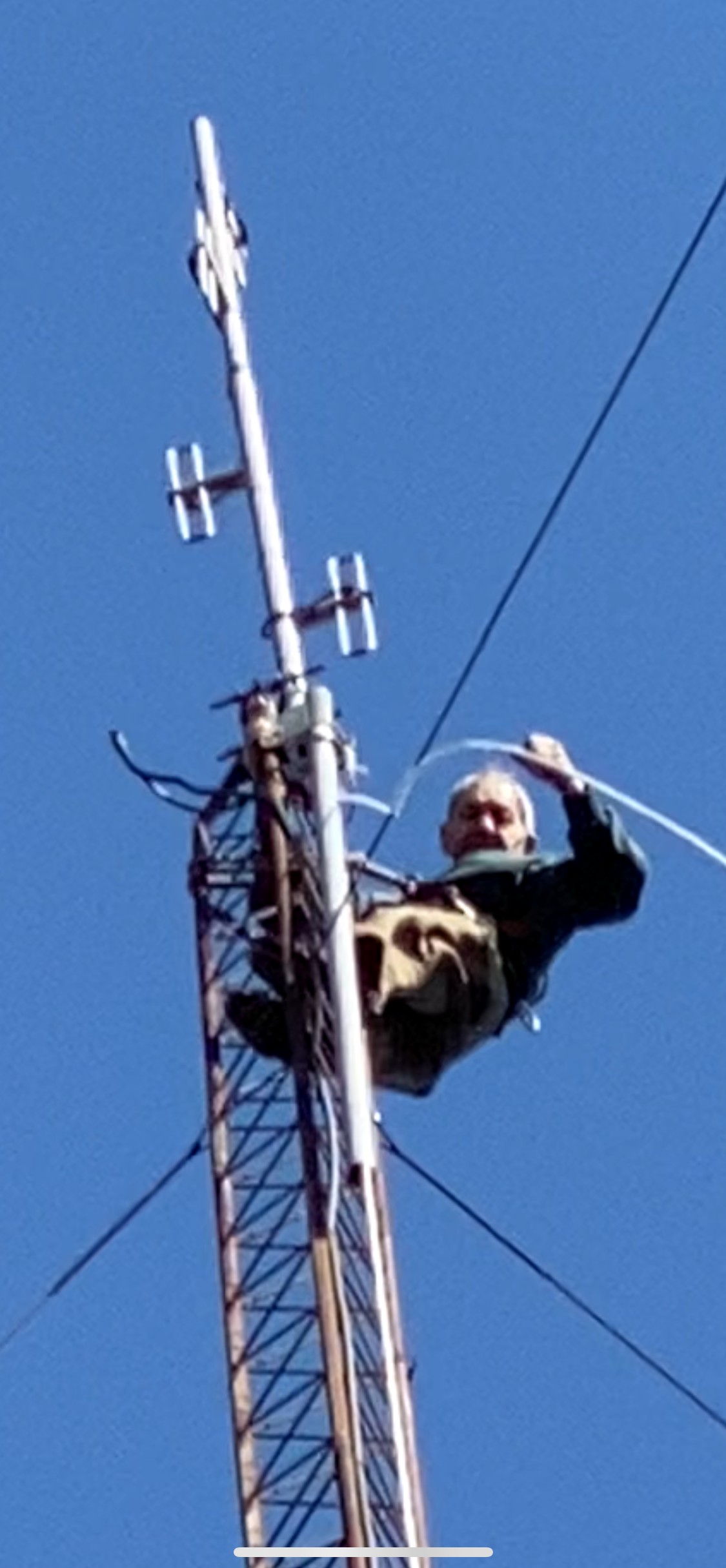

Upon reaching the top of the tower, Bryce could see how the antenna was attached. There had been no way to anticipate that from the ground and it was therefore an important unknown which could affect the entire operation. Fortunately, the attachment was comprised of 2 interlocking clamps which were amenable to disassembly with an ordinary wrench.

The next objective was to raise the ginpole so that its top reached a height greater than that of the antenna. That was accomplished using a 200’ rope as a halyard. As the tower was 100’ tall there was barely enough rope! We encountered our first obstacle while raising the ginpole. The movement of the rope was hindered by a top-hat which covered the pulley. Because of that, Bryce had to perform the arduous task of lifting the ginpole from above. Once at the top of the tower, he clamped it in position and tied the rope to the antenna at a point above its center of gravity (COG.) He then went to work on releasing the antenna from its attachments.

After being freed from the tower, with the assistance of the ground crew pulling on the rope, the antenna was lifted from the tower and lowered to the ground. A second rope, a tagline, was attached to the antenna with a carabiner hook and used to steer it clear of surrounding trees during its descent.

And so the work progressed. The tower was composed of ten 10’ segments, each of which required detachment from the segment below, elevation off of its attachments, and gradual lowering to earth by the ground crew. I record the steps here:

- Attach the ginpole to the tower just below the bolts holding the segment to be removed.

- Raise the ginpole (slide it up through the clamp) so that its pulley is above the segment to be removed.

- Use a carabiner clamp to attach the rope to the segment being removed at a point well above its COG.

- Remove the bolts from the segment being removed. These bolts, having possibly been in place for 30 or more years, could be recalcitrant, and sometimes needed to be broken. There were 6 bolts for each segment, two on each of the 3 legs of the tower.

- Placement of a car jack between the upper and lower segments followed by cranking the jack so that it pushed the upper segment off the lower segment.

- In order to facilitate this process Bryce made 2 metal plates in his shop which fit between the attachments of the upper and lower segments. That allowed a more symmetric distribution of force while jacking the upper segment off the lower segment.

- Lifting the upper segment enough to disengage it from the lower segment was not always easy. Thirty years of rust and seasonal change had led to a “welding” of the attachments, sometimes making the legs of the upper segment difficult to break loose.

- Once detached, the upper segment could be lifted from the tower and lowered by the ground crew with the rope which ran over the pulley of the ginpole, using the tagline for steering.

- After removal of the upper segment, lower the ginpole (slide it down through the clamp), detach it from the tower, and reclamp it below the attachment of the next segment to be removed.

- Guy wires needed to be cut or loosened and detached every 30 feet (3 sets.)

The above sequence was repeated 10 times over the course of about 2 weeks to completely dismantle and remove the antenna and tower. Finally, the base of the tower was cut flush with the concrete block in which it was planted.

The tower will be sanded, painted and restored to good-as-new condition. The antenna will serve as a reliable 2 meter antenna.

The entire procedure had the organization of a military operation (not surprising as most of the crew were in Vietnam or Korea.) Though the process was new to me, I learned quickly from detailed instruction and demonstration. Being included with this group and allowed to participate in this project was a special gift for me which I found extremely rewarding.

THE JOB’S NOT OVER ‘TIL WE HAVE BUZZARDS & BLOOD!

Recent Comments